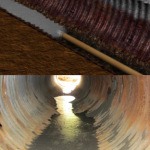

Rehabilitation of infrastructure by mortar spraying

Giving underground infrastructure a second life of more than 50 years

Aging infrastructure such as culverts, catch basins, manholes and even pipes bring serioux problems of parasitic water infiltration, structural loss, corrosion, abrasion and much more.

Contrary to what one might think, the solution is not always to come and replace the product. In fact, for several reasons, it may be advantageous to rehabilitate the existing infrastructure.

Rehabilitation makes it possible to restore the structural capacity of infrastructures at a fraction of the replacement cost, while reducing traffic management. Rehabilitation extends the useful life of these infrastructures by 50 years and does not usually require excavation.

The designs carried out make it possible to take up all the live, dead and hydrostatic loads, thus allowing the pipe to regain its structural integrity.

Centripipe high performance mortar is specially designed for the rehabilitation of large diameter pipes. Made from Portland cement, it contains several additives such as corrosion inhibitors, quartz aggregates and self-sealing additives. In the long term, these additives will minimize the effect of time and extend the lifespan of rehabilitated infrastructure up to 70 years.

The Centripipe high-performance mortar spraying large diameter pipe rehabilitation solution offers numerous advantages in comparison with conventional replacement techniques :

The secret of a very high quality rehabilitation: quality products, a proven method and quality control at all stages.

Allows the culvert to dry during work

1

Removes deposits and contaminants

2

Allows you to redo the profile of the raft in cases where the raider will be very deteriorated

3

Ensures uniformity of the surface and eliminates any trace of infiltration.

4

Allows for structural coating inside the pipe.

5

To carry out throughout the rehabilitation process it allows to validate the good execution of the works and the respect of high quality standards.

6

Learn more about our new service by requesting your presentation or free quote.

Dare to compare our solution with conventional solutions!

In addition to extending the useful life of the infrastructure, rehabilitation by epoxy spraying is a quick and efficient technique, usually requiring no excavation and therefore no additional traffic management.

Discover

Our rehabilitation solution makes it possible to clean and dislodge more than 95% of sediments while protecting it from corrosion for the next 50 years thanks to the addition of a corrosion inhibitor.

Discover