Rehabilitation of Manholes & Underground Structures

No-Excavation Solutions for Underground Structures

Underground infrastructure is aging, and cities and municipalities have increasingly high demands. Over time, problems such as infiltration, leaks, abrasion, and deterioration can arise, requiring infrastructure repairs.

This situation puts a lot of pressure on infrastructure owners, who must ensure the performance of their networks.

Contrary to what one might think, replacement is not always an advantageous option. In addition to being a costly solution, replacement raises issues such as excavation and traffic management.

Our expoxy solution

A technique proven over more than 30 years to extend the life of infrastructure.

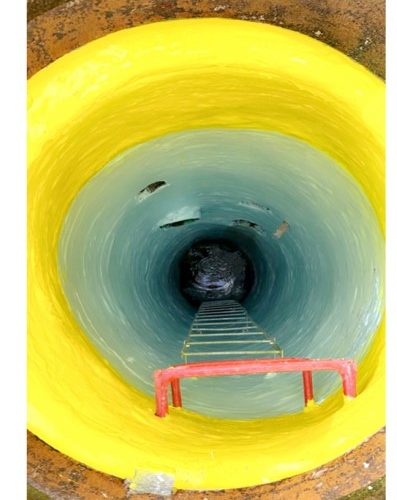

Epoxy spraying rehabilitation, a technique proven over more than 30 years, is one of the few solutions available to extend the service life of aging vertical infrastructure such as manholes, pumping stations, valve chambers, etc.

In addition to extending the useful life of the infrastructure, epoxy spray rehabilitation is a fast and effective technique that does not require excavation and significantly minimizes the impact of the work on citizens.

The structure is first cleaned and then sealed to eliminate any traces of infiltration. Subsequently, the successive application of layers of cementitious mortar, primer, and epoxy restores the infrastructure’s structural capacity and ensures perfect watertightness.

Significant benefits over conventional solutions

Offered at a fraction of the replacement cost, the rehabilitation solution extends the useful life of these infrastructures by more than 50 years.

- Ideal for manholes and infrastructures made of concrete, brick, TTOG, etc.

- Offered at a fraction of the replacement cost

- Quick execution

- No excavation, minimizes impact on citizens and traffic management

- Extends the life of the infrastructure by up to 50 years.

- Eliminates surface repair work

An economical and sustainable process

Frequently Asked Questions

Everything you need to know about rehabilitating manholes/catch basin using epoxy spraying

In which cases is epoxy recommended?

This type of rehabilitation is particularly suitable for underground infrastructure that has suffered advanced deterioration caused by aggressive chemical environments, such as corrosive gases or acidic effluents. Epoxy is also very useful for restoring valve chambers, manholes, sumps, and pipes where infiltration or loss of watertightness is a problem. Its rapid application, without excavation, makes it an ideal method in urban contexts or in confined spaces.

What types of structures can be rehabilitated using this process?

Epoxy spraying can be applied to a wide variety of concrete structures, both horizontal and vertical. These include valve chambers, manholes, small and medium diameter pipes, retention basins, sumps, and other water management structures. The process is flexible and can be used in industrial, municipal, or residential environments.

What are the advantages over a complete replacement?

This process avoids costly excavation work, significantly reduces service interruptions and impacts on the urban environment. It allows for rapid and safe recommissioning of infrastructure, while providing lasting protection against corrosion and infiltration. It is a method that is economical, sustainable, and environmentally friendly.

What is the lifespan of epoxy coating?

Epoxy coating offers a lifespan of over 50 years, depending on conditions of use. It forms a highly resistant chemical barrier that protects the concrete substrate against corrosion, abrasion, and chemical attack. Its durability depends in particular on surface preparation, the thickness applied, and the chemical environment to which it is exposed.

How does the rehabilitation process work?

The process involves several key steps: first, the surface is thoroughly cleaned to remove contaminants, deposits, or corrosion. Next, the surface is prepared to ensure excellent adhesion, often by sandblasting. The epoxy is then sprayed on in several passes to form a continuous coating. Curing is rapid, allowing the structure to be put back into service quickly.

Is epoxy resistant to harsh environments?

Yes. Epoxy is formulated to resist corrosive gases, aggressive effluents, constant humidity, abrasion, and thermal cycles. This makes it the material of choice for concrete chambers and pipes exposed to sanitary or industrial environments.

Is the hydraulic capacity affected?

No. Epoxy is applied in very thin layers, and its smooth finish can even improve hydraulic performance by reducing friction. Unlike some lining or replacement techniques, the useful cross-sectional area of the pipe is therefore preserved.

How long does the work on a construction site take?

The duration depends on the size of the structure, its accessibility, and the extent of deterioration. In general, the work is completed quickly: a few days are sufficient to clean, prepare the surface, apply the epoxy, and allow it to cure. All this with minimal disruption to the environment or the operation of the facilities.

Do you offer a warranty on this type of work?

Yes, every project carried out using the epoxy spraying process is subject to a rigorous quality control process. We offer guarantees on materials and workmanship, tailored to the requirements of the site. Inspections can also be carried out after the work is completed to validate the compliance of the coating.

Our Projects